Electric Oven Not Heating? Troubleshoot Bake and Broil Elements

⚠️ CRITICAL SAFETY WARNING

Electric ovens operate on 240 volts, which can be fatal. Always disconnect power at the circuit breaker and verify the oven display, lights, and clock are completely off before beginning any inspection or repair work. Never attempt electrical repairs while the unit is connected to power.

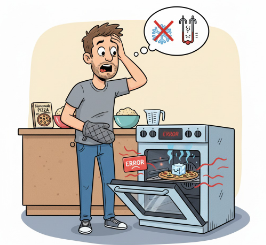

When your electric oven suddenly stops heating, **faulty heating elements are responsible for 65% of all cases**. Before calling a repair technician, you can often diagnose and fix the problem yourself with proper safety precautions and basic testing equipment. This comprehensive guide will walk you through systematic troubleshooting to identify whether your bake element, broil element, or another component is causing the heating failure.

Understanding Electric Oven Heating Systems

Electric ovens require **240 volts of alternating current** supplied through two 120-volt legs to operate properly. The heating system consists of two main elements: the **bake element** (bottom) provides approximately 80% of the oven’s heating capacity, while the **broil element** (top) contributes about 20%.

When you select a cooking mode, the oven control board sends voltage to the appropriate element, causing it to heat and glow red-orange. Temperature is maintained through cycles controlled by either a temperature sensor or thermostat, which monitors internal temperature and signals the control board to turn elements on and off as needed.

Primary Causes of Electric Oven Heating Failure

1

Faulty Heating Elements (65%)

Bake Element Issues: The bake element, located at the bottom, is the most common failure point. When it fails, your oven may heat poorly or not at all.

Broil Element Problems: If only the broil element is faulty, you may notice slightly longer cooking times but less dramatic heating issues.

2

Electrical Supply Problems (20%)

Electric ovens operating on 240 volts can experience heating issues when one leg of voltage is interrupted by a tripped breaker or blown fuse. **There may be enough power to keep the display illuminated while preventing elements from heating**.

3

Temperature Sensor Malfunction (10%)

The oven temperature sensor probe can fail without warning, potentially causing error codes or complete heating failure. The sensor typically measures around **1,080 ohms at room temperature**.

4

Control Board Failure (3%)

Power surges from lightning strikes or electrical storms are a leading cause of electronic oven control board failure. When the control board fails, it may not send power to heating elements despite appearing to function normally.

5

Thermal Fuse Failure (2%)

Thermal fuses protect ovens from overheating by cutting power when temperatures exceed safe limits. **When blown, they prevent heating elements or the entire oven from receiving power**.

Visual Inspection of Heating Elements

Signs of Element Failure to Look For:

Blistering

Surface blistering indicates wear from excessive heat or age

Cracks or Breaks

Visible damage is a definitive sign replacement is needed

Dark Spots

Failed elements often show dark spots, blisters, or discoloration

Scorch Marks

Burns or scorch marks suggest overheating has occurred

Step-by-Step Testing Procedure:

- Remove oven racks for better access to elements

- Set oven to appropriate mode (bake/broil) and wait 3-5 minutes

- Observe if elements glow red-orange – working elements should heat uniformly

- Document findings with photos if replacement is needed

Multimeter Testing for Continuity

Equipment Needed

Step-by-Step Testing Procedure

1

Setup Phase

- Ensure complete power disconnection – verify oven display is completely dark

- Configure multimeter: Connect black probe to COM socket, red probe to VΩ socket, then set to ohms (Ω) setting

- Access heating elements by removing necessary panels

2

Testing Process

- Disconnect element wires (photograph connections first for reassembly)

- Calibrate multimeter by touching probes together (should read 0.00 or beep)

- Test element terminals: Press probes against the two terminals on the heating element

- Record readings – working elements show resistance between 19-115 ohms

Expected Readings

✅ Good Elements

Readings typically range from 19 to 115 ohms. A 2500W bake element should read approximately 20-25 ohms.

❌ Failed Elements

Display infinite resistance (no continuity) or near-zero resistance, indicating element failure.

Advanced Troubleshooting When Elements Test Fine

Temperature Sensor Testing

The temperature sensor is a thin probe located at the back of the oven that functions as the oven’s thermostat. **Test the sensor by measuring resistance – it should read approximately 1,080 ohms at room temperature**.

Common Sensor Issues:

- Physical damage from cleaning or moving

- Calibration drift over time

- Wire harness connection problems

- Internal component failure

Grounded Element Testing

To test for a grounded element, place one multimeter probe on the element’s outer surface and the other on an element terminal. **If continuity exists, the element has shorted and must be replaced**.

Control Board Issues

When heating elements and sensors test good, the control board may be faulty. Recent surveys indicate that **30% of oven issues are linked to faulty control boards**.

Signs of Control Board Failure:

- Erratic temperature control

- Error codes displayed on screen

- Intermittent oven function

- Complete loss of heating despite good elements

Electrical Supply Verification

Power Requirements

Electric ovens require **240 volts across two 120-volt legs**. The outlet should provide **220-240 volts between hot terminals** and **approximately 120 volts from each hot terminal to neutral**.

⚠️ Voltage Testing Safety

Voltage testing requires extreme caution and should only be performed by those comfortable with electrical systems. **Live voltage testing poses serious shock and electrocution hazards**. If you’re not comfortable working with electrical systems, contact a qualified electrician.

Testing Procedure for 240V Outlets:

- Set multimeter to AC voltage setting with range capable of reading up to 250V

- Test hot to neutral: Should read approximately 120V on each leg

- Test hot to hot: Should read 220-240V between the two hot terminals

- Verify readings: Low voltage indicates electrical supply problems

Common Electrical Issues

Tripped Breakers

Check that both legs of the 240V circuit are functioning. A single tripped breaker can leave displays powered while preventing element heating.

Loose Connections

Inspect terminal blocks for burnt or loose connections, which are common near heat sources.

Thermal Fuse Testing and Replacement

Understanding Thermal Fuses

Thermal fuses protect ovens from overheating by cutting power when temperatures exceed safe limits. **When blown, they prevent heating elements or the entire oven from receiving power**, often requiring complete replacement before the oven will function again.

Location and Access

The thermal fuse is typically located behind the rear access panel, often near the bake or broil element terminals. It appears as a **small plastic component with two wire terminals**.

Testing Procedure:

- Disconnect power and remove rear access panel

- Locate thermal fuse near element terminals

- Disconnect fuse wires and isolate component

- Test with multimeter set to ohms/continuity setting

- Good fuse: Shows 0-1 ohm resistance or continuity beep

- Blown fuse: Shows infinite resistance (no continuity)

Professional Repair Recommendations

✅ Generally Safe for DIY

- Heating element replacement (with proper safety precautions)

- Visual inspections and basic testing

- Temperature sensor replacement

- Basic control board resets

⚠️ Requires Professional Service

- Thermal fuse replacement and root cause diagnosis

- Control board replacement and programming

- Internal wiring repairs

- Electrical supply problems at breaker panel

When to Call a Professional Immediately:

- Any gas-related issues or suspected gas leaks

- Multiple simultaneous component failures

- Burning smells or visible damage to wiring

- Uncomfortable performing electrical testing

- Repeated component failures after DIY repairs

Cost Analysis and Decision Matrix

Element Replacement

Professional Service

Control Board

Thermal Fuse

Repair vs. Replace Decision Framework

Consider Repair When:

- Oven is less than 10 years old

- Single component failure identified

- Total repair cost under 50% of replacement value

- Good overall condition of other components

Consider Replacement When:

- Oven is more than 10-15 years old with multiple issues

- Repair costs exceed 60% of new oven price

- Energy efficiency improvements desired

- Repeated failures of different components

Preventive Maintenance and Troubleshooting Guide

Extending Element Life

Regular Cleaning

Clean oven interior monthly to prevent buildup that can damage elements

Avoid Foil Lining

Don’t line oven bottom with foil as it can cause overheating

Self-Clean Sparingly

Use self-cleaning feature sparingly as extreme temperatures stress components

Gentle Cleaners

Use gentle cleaning products to prevent element damage

Recommended Maintenance Schedule

📅 Monthly Tasks

- Clean oven interior and check door seals

- Verify proper door closure and operation

- Test oven temperature with thermometer

📅 Annual Tasks

- Professional inspection recommended

- Calibration check with oven thermometer

- Visual element inspection for wear signs

⚡ Quick Diagnostic Reference Guide

🕐 Immediate Checks (5 min)

- Verify power and circuit breaker

- Check oven settings and door closure

- Look for obvious element damage

- Test display and controls function

🕒 Basic Testing (15 min)

- Visual element inspection during heating

- Simple continuity test with multimeter

- Temperature verification with thermometer

- Check for error codes

🕕 Advanced Diagnosis (30-60 min)

- Complete element resistance testing

- Temperature sensor evaluation

- Control board reset attempt

- Thermal fuse continuity testing

Conclusion

Electric oven heating problems, while frustrating, are often diagnosable and repairable with proper knowledge and safety practices. **The most common cause is a burned-out heating element (65% of cases), which can often be determined by visual inspection combined with multimeter continuity testing**.

Remember that safety is paramount when dealing with 240-volt appliances. Always disconnect power at the circuit breaker before beginning any inspection or repair work. When in doubt, consult with qualified appliance repair professionals who have the experience and tools to diagnose complex electrical issues safely.

By following this systematic troubleshooting approach, you can often identify the root cause of your oven’s heating problems and make informed decisions about repair versus replacement options. Most heating element failures can be resolved with a $20-50 part and basic DIY skills, potentially saving hundreds in professional service calls.

Need More Appliance Help?

Check us out for more appliance repair guides, parts, and expert advice at

Frequently Asked Questions

How do I know if my oven heating element is bad?

Look for visible signs like blistering, cracks, or dark spots on the element. Turn your oven to bake mode and wait 3-5 minutes – a working element should glow bright red-orange. If it doesn’t glow or only parts glow, the element needs replacement. You can confirm with a multimeter test showing 20-25 ohms resistance for a good bake element.

Can I replace an oven heating element myself?

Yes, replacing a heating element is generally safe for DIY repair if you follow proper safety procedures. Always disconnect power at the circuit breaker first, take photos of wire connections before removal, and ensure you purchase the correct replacement element for your oven model. The repair typically costs $20-50 for the part versus $150-350 for professional service.

Why does my oven have power but won’t heat?

This often occurs when one leg of the 240-volt power supply is interrupted while the other leg powers the display and lights. Check your circuit breaker to ensure both legs are functioning. Other causes include a blown thermal fuse, faulty temperature sensor (should read 1,080 ohms at room temperature), or a failed control board that isn’t sending power to the heating elements.

What safety precautions should I take when troubleshooting my electric oven?

Electric ovens operate on dangerous 240-volt current that can be fatal. Always disconnect power at the circuit breaker and verify the oven display, lights, and clock are completely off before starting any work. Never attempt repairs while connected to power. Use insulated tools, wear safety gloves, and if you’re uncomfortable with electrical work, contact a qualified professional technician.